NCI Future of Feeding Webinar Series | Featuring Kurt Rosentrater

Kurt Rosentrater, Associate Professor at Iowa Sate University

Each month, NCI holds a new update in the Future of Feeding webinar series, which focuses on using innovation in the processing of animal food, the equipment being used, as well as using grains from our region for coproducts. This month, we featured speaker Kurt Rosentrater, an associate professor at Iowa State University. Kurt presented on Beyond DDGS, Corn Gluten Meal, and Corn Gluten Feed: Current and Evolving Products from Corn Processing. These coproducts and byproducts from the three most common types of corn processing are DDGs, corn meal, and corn feed.

Why should we care about this? The livestock industry will only continue to grow due to the demand for meat, milk, and eggs. What animals consume will affect what the animal produces, which we consume. Kurt began his discussion with the motivations behind corn processing, sharing each cattle’s maximum inclusion rate with beef cattle at 20-40%, dairy cows at 10-30%, market swine at 10-40%, and poultry at 10-15%. As a grain processor, Kurt addresses how the industry is moving away from the term byproducts and instead using main products and feed products.

Coproduct Quality and Value

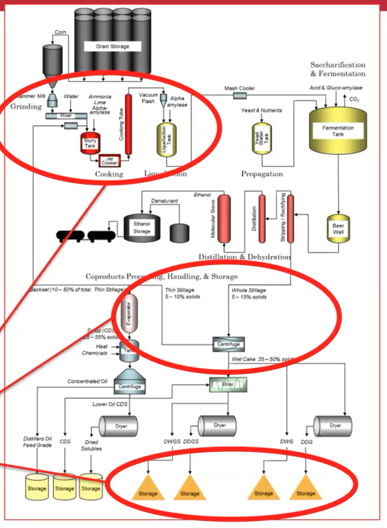

The manufacturing of dry grind ethanol has shown great growth, over twenty years ago ethanol plants that were producing 450 MLY were the largest at the time and today we are experiencing some that are making double that. The process behind these dry grind ethanol plants is first, the corn is grinded, water is added and then enzymes, a cooking step is used at some plants, additional enzymes are added to break the scratch down into shorter chains so the yeast can get to the glucose molecules. Then the liquified starch is put in a bioreactor, where yeast will consume the glucose to produce the alcohol. Sustainability in this process is something that is getting developed with how to capture the CO2 produced by the yeast metabolism and reuse it in some way. Over one third of an ethanol plant’s energy is used on their byproducts.

Ethanol coproducts include DDGs, made of primarily protein, fat, fiber,minerals, residual yeast cells, distillers wet grains, and condensed soluble that leave the evaporators. DDGs have between 25-34% protein, which is important for livestock producers to be aware of when feeding their livestock.

Diagram of fiber and protein separations process

The dry milling process looks a little different than alcohol production, since it is for food products the corn will be washed, screened, dried, degermed, grinded, and sifted through to be separated by corn grits, corn meal, and corn flour. The portion that doesn’t make it through the degermination stage will be turned into hominy feed, which has half as much protein of the DDG. The difference between the dry mill and the wet mill, is that the dry mill will not give you a complete separation of the protein, fat, fiber, and minerals because the point is to concentrate them, it is the wet mill’s function is to completely separate them.

The maize wet milling will produce a clean separation of all the components. A clean separation of the germ, and grind the residual primarily the protein starch and brand, then undergo a series of washers to have a clean starch screen. The end product is corn gluten meal or corn gluten feed.The percentage of protein in the corn gluten meal is 67%, which is over triple of that in corn gluten feed at 21%, with dried distillers grains (DDG) between the two in protein percentage.

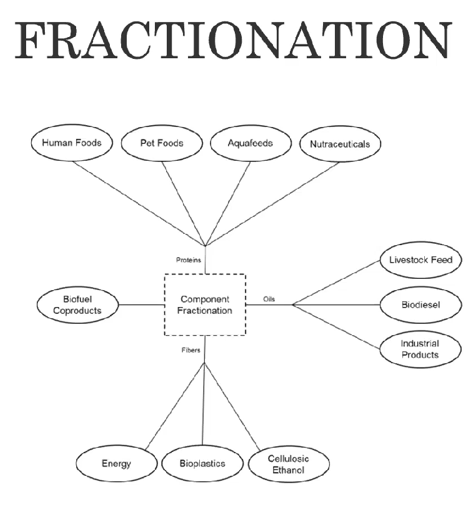

A diagram of fractionation

Kurt touched on the evolving processes and new opportunities of corn processing, starting with fractionation. Fractionation is the process of taking the protein from the fiber and from the fat. The proteins can be used in human food, pet food, aquafeeds, or nutraceuticals markets, the oils can be used for livestock feed, biodiesel, or industrial products, and the fibers can be used for energy, bioplastics, and cellulosic ethanol. The composition trend over the last two decades have shown a decrease in fat in DDGs because the dry grind industry has technologies that separate the oils prior to fermentation. The fiber has risen because of this, but the starch has also decreased due to plants being used more efficiently. There are a few companies that are ahead of the game in separating the protein and fiber from the distillers grains. These five companies are D3Max, Fluid Quip Tech, Marquis, ICM, and Quad County.

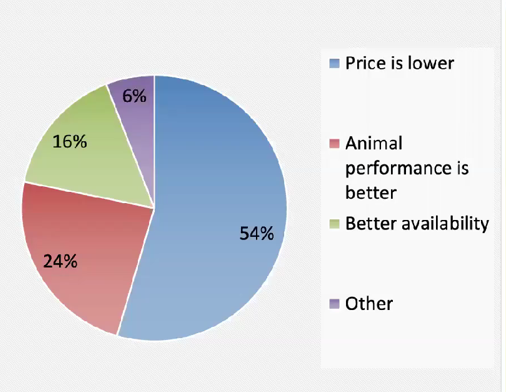

Pie chart of reasons behind using coproducts for feeding

Why do farmers use feed coproducts? Majority of farmers' reasoning is the low price and the increased animal performance, along with the sufficient availability. Kurt enlightened viewers with his extensive knowledge behind corn processing, the impact it has, and why it is utilized. With the livestock industry growing, what livestock consume is important to just about everybody and DDGs, corn meal, and corn feed are a substantial part of it.

For more information about future webinars offered at NCI, click here.

To watch the recording, click the video below.