The NCI Pasta Processing Laboratory is a food safe space equipped to demonstrate the impact of raw materials and processing on end product quality for traditional pasta, ravioli and gluten-free pasta*. It is available for product development, process testing, and training. The pilot-scale equipment provides a scalable solution for pasta innovation.

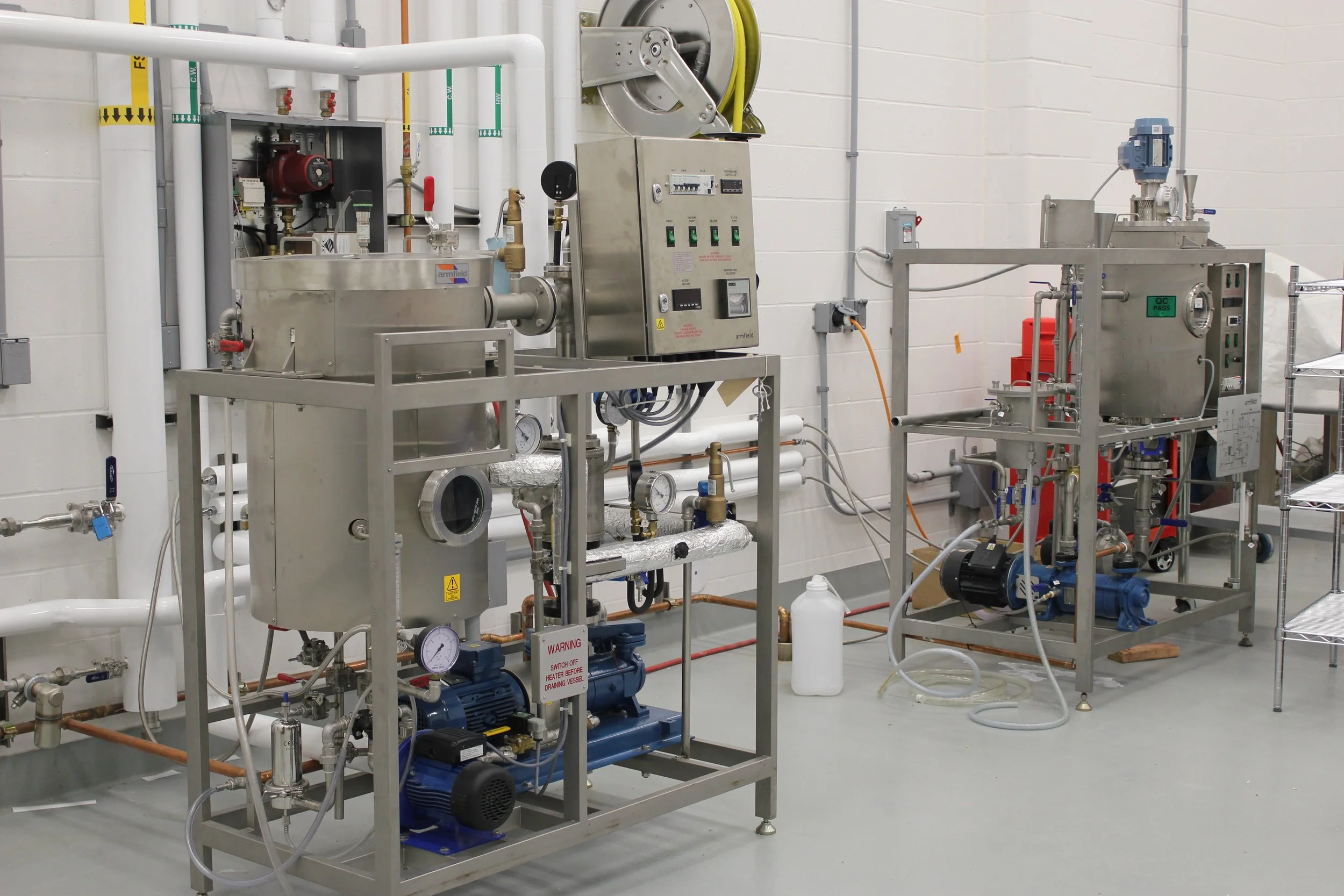

Read MoreThe NCI Soy Foods Laboratory is a key part of our technical services, providing a fully food-grade space for developing, testing, and producing soy-based and plant-based foods. We specialize in a variety of products, including soymilk, tofu, natto, tempeh, miso, and plant-based beverages.

Read MoreThe Extrusion Laboratory is equipped with a Wenger TX-52 twin-screw extruder for demonstrating the impact of raw materials and processing conditions on the organoleptic, textural, and nutritional characteristics of these foods.

Read MoreThe NCI Baking Laboratory is a state-of-the-art facility dedicated to instructional use. Our lab supports a wide range of baked goods, including pan breads, tortillas, buns, artisan breads, cookies, cakes, and more.

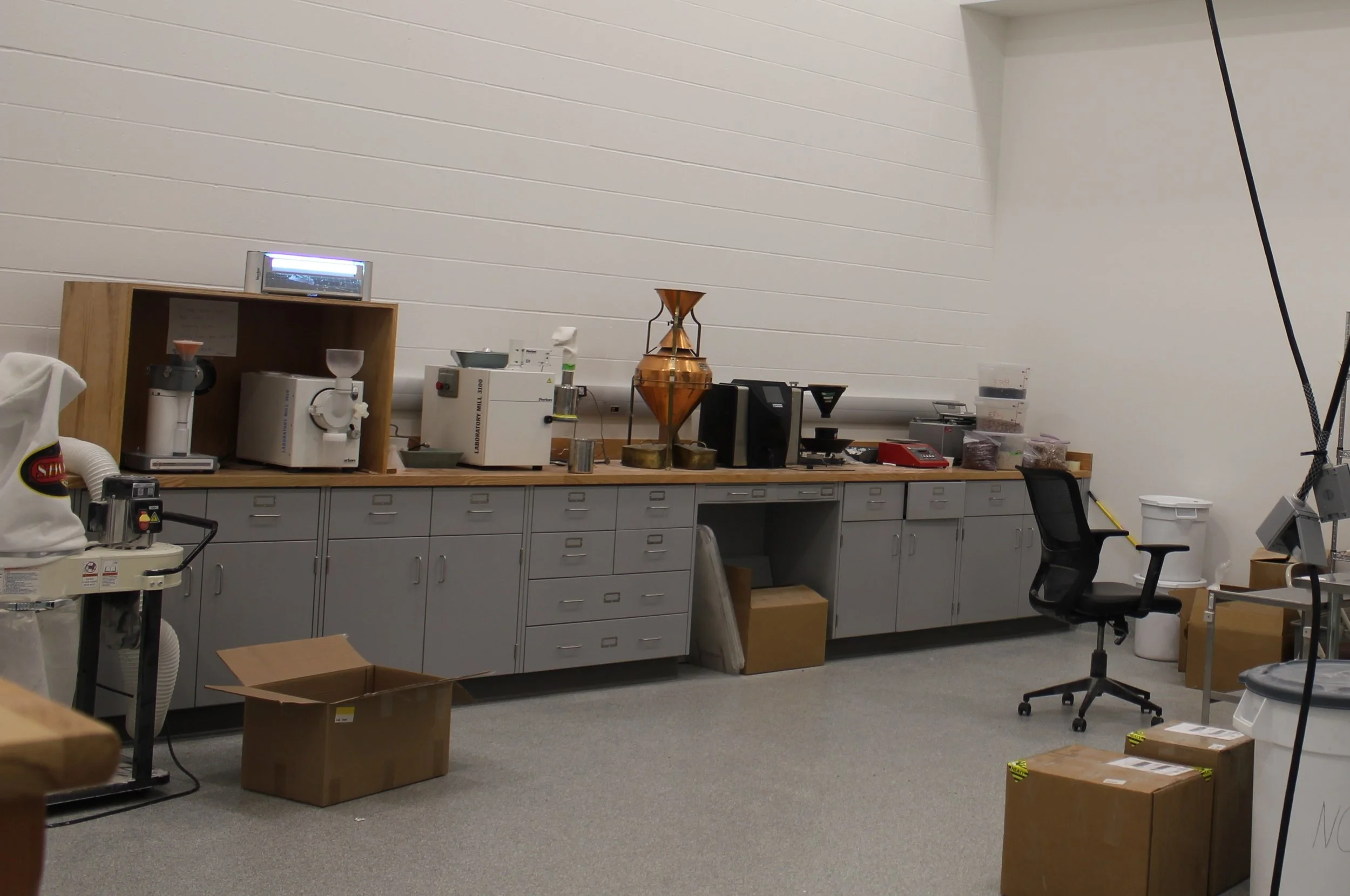

Read MoreThe Analytical Laboratory is equipped to evaluate oilseeds, whole grain, milled products, and finished products in a quality control environment with an array of equipment and instruments.

Read MoreThe pilot-scale mill is capable of milling spring wheat, winter wheat, or durum wheat into refined flour, whole wheat flour, or semolina, respectively. These products can be used for testing flour quality, baking/processing evaluation, and pasta quality evaluation.

Read MoreNCI has full pilot-scale capability for oilseed extraction on a wide variety of crops. Our scientists can help you with analyzing oil content and quality, as well as produce defatted meal for human food applications or protein analysis.

Read MoreStone milling is one of the latest additions to our facilities at NCI. In line with our mission, we've embraced the growing trend of producing nutritionally rich stone-milled and whole grain flours. We are equipped with a 26-inch granite stone mill with a 100-pound capacity grain hopper, along with a controlled grain feeder and flour sifter.

Read MoreNew to the NCI is a full sensory kitchen and separate testing room for individual consumer sensory panels. This allows us to conduct product development and ingredient testing to the highest standard to collect consumer feedback.

Read MoreNCI's Feed Production Center serves as an educational and technical assistance center specializing in feedmill management and feed manufacturing technology for international and domestic clientele. Facilities include a twenty seat classroom, quality assurance lab, lobby, and general reception room. Daily production capacity is 60 tons of meal feed, or 24 tons of pelleted feed.